We needed to make an old fashioned bathing suit for the character of "the lifeguard".

Sort of like the gentleman second from the left in this photo.

First the material- we used a wool/Lycra blend from Whaleys which for some reason I cannot find listed on their website- I hope it has not been discontinued! It is really fabulous fabric. Pricey- yes, at $78/ yard (2008 pricing from our stock tag) but for specific projects like period tights or period bathing suits, nothing else that I have used compares to it. Anyhow, being wool it does shrink too, so a wash and dry to preshrink it was necessary.

For the red stripes, we used a lightweight poly cotton colourfast knit that was cut into 3" strips and laid on top of the wool/Lycra base.

It is important to make sure the red was not going to run and turn the whole thing pink!

I had to make a few pattern decisions right off the bat. There are a few options for making this pattern.

Breaking it down- where do we want the seaming to be?

It could be an all in one unitard pattern- no waist seam. These unitards often have no CF seam at all. Sometimes they have a side seam, but many do not. In that case the pattern would have to have a CB seam from the neck down through the CB of the seat. All the body shaping happens through that one seam.

I didn't think that a CB seam in the bodice area would look right. Plus I am applying stripes, and that didn't seem like a good shape for this.

So I decided that the bodice should like a tank top, with only side and shoulder seams.

That leaves the lower section to think about.

Normally a pair of shorts has a waistline, CF, side and CB seams to shape around the body. I decided to not have a CF seam in the shorts, allowing the stripes to be applied flat across the front.

I decided to keep the waist seam, which would allow me to fit and adjust the garment length very easily.

Since we were applying stripes, I figured that a stripe could be used to disguise the waist join.

That meant that the back of the shorts would have a CB seam and all the length required through the fork or crotch extensions would be on the back piece.

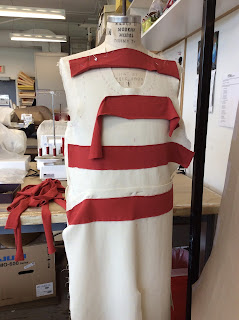

This is the first fitting, cut right into the fabric and zigged together.You can see that I have pinned some length out of the bodice section. This was just at the back waist not in the front.The designer did not want this fit very tightly to the body, so I left the overall fit around the body as is, and honestly the waist seam allows a good fit without it being stretched to the limits.

I basted on a few stripes to confirm their width. I thread marked the neckline and armhole lines but did not insert any elastic at this point as I wanted to confirm the design lines.

The next step was to mark the alterations, take it apart, cut the stripes and start sewing them to the base. We used a coverstitch machine to apply the stripes. The only tricky part was that we worked from the inside as we wanted the covering threads to cover the raw edge of the red stripes. The usual double line stitch of the coverstitch was now on the inside.

You can see the inside of the fronts more clearly here with the stripes applied.

At the waist we joined the bodice to the shorts with a flat overlapped seam rather than a regular seam so the join would not be noticeable. Again we used the coverstitch for this.

The same technique was used to put the shoulders together. This is much less bulky overall. The only seams that had regular four thread serging were CB of the shorts, inseam and the side seams.

The stripes on the front of the shorts section will determine how we place the stripes in the back section. If this were pre-striped fabric I would not be able to control the look of the stripes overall, and would likely have to cut this quite differently.

On the back of the shorts section, the CB seam was joined first, then it was attached to the back bodice. Then the stripes were applied.

You can see here that the third stripe down from the waist takes a drastic turn from the side seam under the seat, then over to the inseam. The stripes will match at the side seam, and will also match to the corresponding stripe on the front inseam.

This is where a pre-striped fabric will be a problem visually! It would never match up to the front at the inseam. Here we can manipulate things to be as we want them. Very tricky, don't you think?

Once all the stripes had been applied, the shoulders were sewn, and then the sides and inseam.

The final process was to finish the neckline and armholes. We wanted to install elastic in those edges but not in the usual manner of zigging or serging the elastic in. This seemed too thick to do that successfully. So we serged those seam allowances down to a scant 1.5cm, turned them to the inside and stitched a half inch away to form casings, then fed elastic into the armholes and neckline. We could then adjust the length of the elastic as needed at the next and final fitting as seen below.

How much fun is that?

It was a good project to stretch (haha) my pattern making and our sewing techniques.

cheers!

What a FUN project! I always enjoy it when these type of projects come across my table, too - it's a great way to break up the monotony of suits and such. Looks ADORABLE!!

ReplyDeleteThanks! It is very cheery!

ReplyDeleteAmazing! When you first said you'd do applied stripes, I thought you were going to make it as a copy of the photo, with those thinner stripes, and figured it would just be hell! But this is great -- so bold and fun, and very much of the period look. My grandad was the NY state underwater swimming champion in 1915, and I imagine he wore a suit much like this, and wool, too, to keep him warm in those frigid waters,

ReplyDeleteThanks"

Yes, I am glad the designer wanted wide stripes too!

DeleteI wonder what it was like to swim wearing wool!! Heavy no doubt.

Actually... My fave suit when I was 14 was a dark marine blue wool one-piece with a slightly low back. I felt so fashionable! It didn't drag at all in the water,fit very well, except of course at the bustline

DeleteWell, I remember, my mother had a wool 2 piece swim suit. And she often said it was better to wear than the lycra stuff later. You would not have call it a bikini! Think 3oer. I assume, they would have insert a gusset instead of what you did. Beause it was knitted on the machine and you had as few seams as possible as you stated. But your work is genial. And so refreshing considering gent's wear. Congratulation

ReplyDeletelg

heidi

A couple of things. First, what a fantastic result you got from all that careful rearranging of the stripes. Second, what pattern do you think the original swimsuit used? I would think the no seam front, with CB zipper. And last, could your swimsuit have been done in a heavy weight cream colored Lycra with red Lycra stripes? This could be the community theater version. Just thought of another version, the white Lycra with spray painted stripes version. In fact I just completed a school mascot that needed a blue pinstripe baseball uniform, and I masked and spray painted the 3/4" stripes. I got good results, but there was a little bleeding from the tape not adhering to the fabric. Maybe next time I can convince them to use your coverstitch strip technique.

ReplyDeleteYou could sew fabric together to make the stripes but then the stripe matching would be quite off unless you changed the pattern to a seamed trouser front shape.

DeleteSpray painting, sure, i dont see why not if you need a quick and inexpensive method.