Once I have fused all the fabric and it is cut out, the pieces need to be marked. The style lines need to be seen from the right side of the fabric and some areas need to be stayed to prevent stretching out. Since we are in the fashion fabric, that means most of the marking is done by hand. This coat will come apart after the fitting, so it is essential to have everything marked beforehand.

Here is a partial half scale pattern of the body of the coat I made for you. I made this pattern with a side body panel, not true to period but it gives a bit more shape through the torso and a bit more flare to the skirt at the sides of the body.

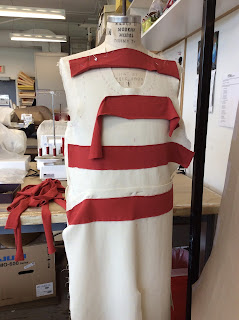

Next, I have to think about structure. Which areas need support and what materials are available to give the support needed.

I need a chest canvas- and for this I purchased an overcoat length canvas. Like this one but longer. I need to make some modifications to it. I want the chest area to remain in its normal position, but I don't have a lapel, so I want to add in a piece of hymo so there is a double layer across the front.

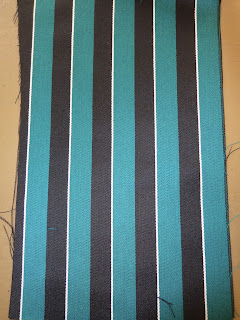

I cut the coat with the straight grain parallel to the front edge of the skirt as shown here.

I have found that this reduces the issue of excessive bias stretch along the front edge. it also looks better in striped fabric, as the stripes don't run off the edge!

The chest canvas, from approximately the waist down, is modified by darting it out and slightly shifting the lower area in sections so the grain of the canvas is the same as the coat. The darts are cut out, then joined edge to edge with a strip of fusible interfacing and zigged to hold.

I also need to give the skirt areas support so they don't collapse. We want the skirts to have some oomph to them. Support inside the skirts is also useful because we will be sewing trim on the skirts and the support will stabilize those areas.

I used a product called Sew Sure firm. This is a narrow sew in interfacing that I have used many times in the past. It used to be available in a number of weights/stiffness from soft to extra firm, but I think now is only available in firm and soft. I use this crosswise so it naturally resists folding flat in the folds/pleats of the skirt.

I draw out my pattern on the sew sure, and it is then flat mounted to the skirts by hand, down the pleat lines as well as around the perimeter. The Sew Sure that we put in the skirts also benefits us when it is time to hem the coat- there is something to cross stitch the hem allowance to!

Other areas needing support are the cuffs. here I will use a piece of the sew sure, and a piece of fusible canvas/hymo to give me the required stiffness. Pictures and details later!

The collar also needs a support, and for this I use a laminated piece of hymo and collar linen. The collar is cut nett (no seam allowances). This is mounted onto a piece of thin cotton which will act as a seam allowance. Pictures and details to come!

Similarly to the coat, the waistcoat fronts are cut out, a piece of hymo is cut for the fronts and basted in for the fitting. The waistcoat back is just a piece of muslin for the fitting. A collar is cut and mounted to cotton, then basted in place.

Lining- I generally cut the lining for the sleeves for a fitting- it helps slide them on and off, and I cut the back body lining, again so the garment slides a bit more easily over the waistcoat and sits on the body without friction.

I cut the rest of the linings as well as the waistcoat back after the first fitting.